Its relationships with its customers have been a key ingredient in its success: the integration of sectors, excellent performance and superior quality of work are the achievements of the companies who have placed their trust in Mini Motor.

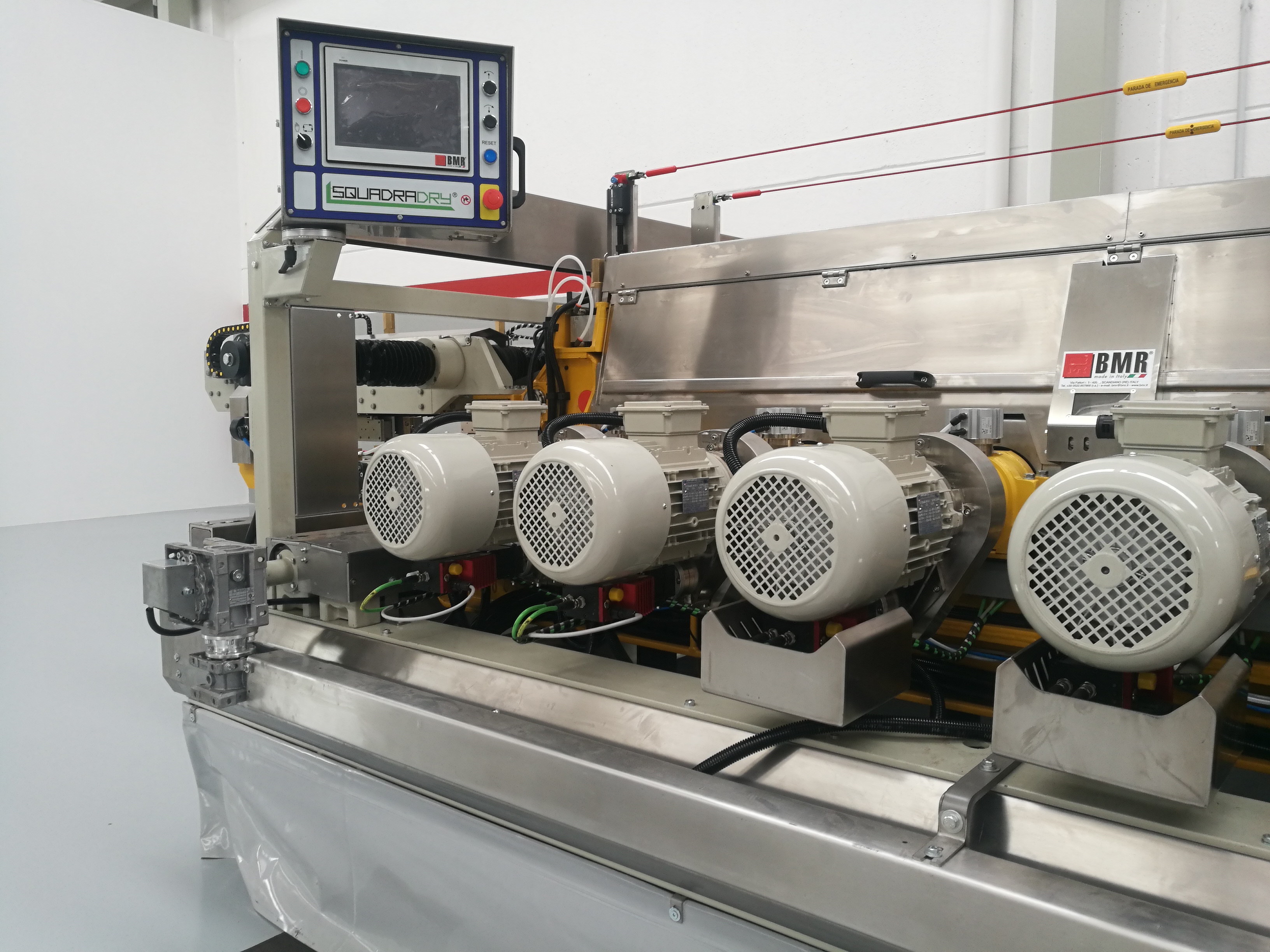

BMR

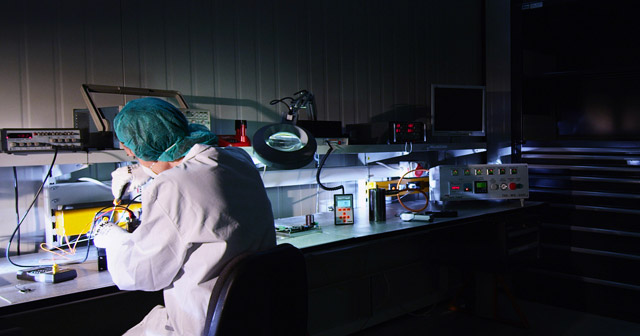

For more than 50 years now, Mini Motor has been designing and manufacturing innovative solutions for automation and motion control.

Our experience with BMR

Mini Motor’s partnership with BMR comes within a context of Industry 4.0: BMR is a leader in the ceramics industry with over 50 years of experience in the design and construction of machinery and technology for end-of-line production processes.

As an acknowledged major player in its field, specialised in the processing and machining of large slabs and tiles through grinding and bevelling, BMR chose to apply Mini Motor’s technological solutions to its latest-generation grinding machines.

Technology 4.0

The introduction of technology 4.0 has done away with the manual setting of parameters previously handled by a machine operator, as they are now completed with the assistance of geared motors: Mini Motor’s DBSE series in the case of BMR. Having brushless motors at the end-of-line in production gives BMR several advantages.

- The adjustment of the machine settings is more precise and the DBSE motors make it possible to read the statistics relating to the reactivity of the machinery itself, guaranteeing permanent setting adjustment.

- Less wear and, consequently, lower costs for diamond tools, as they are adjusted more precisely for optimum performance.

- Enhanced grinding precision as the squaring machine works the tile that has just been cut out of the large slab.

- Increased production speed and improved percentage of prime-quality production.

- Less pollution in terms of sustainability thanks to the application of dry technology (no need for waste-water disposal).

Tangible benefits marking the start of a successful, long-lasting relationship between Mini Motor and BMR.

request information

(*) informazioni obbligatorie